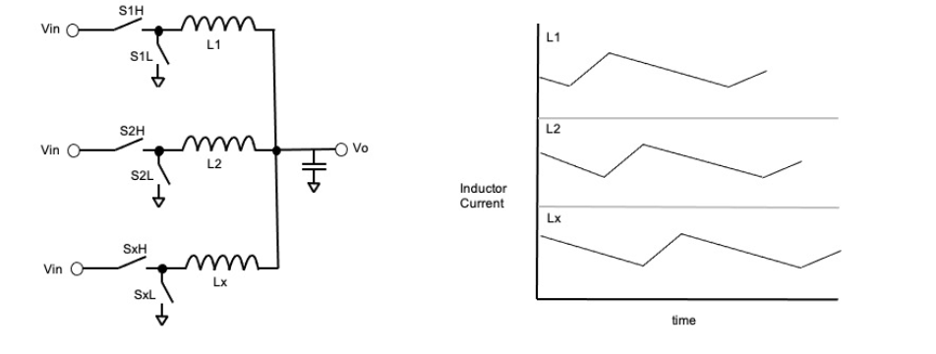

Pulse is expanding their portfolio of high current, low DCR inductors used in single phase PoL and multi-phase buck converters to power processors, memory modules, FPGAs and ASICS in servers, datacenters, networking systems and graphics cards. The three new families provide lower core loss using the latest high frequency materials, reduced DCR, and higher current ratings in different footprints, the thinnest one is only 4.6mm max with 140A Isat max. These multi-phase buck topologies distribute the current among multiple parallel ‘paths’ with staggered turn off and turn on. By operating each phase in a staggered fashion, the ripple currents in each phase tend to cancel at the output and the overall ripple current seen at the load is much smaller than the ripple on each phase. This approach allows smaller inductances to be used (typically on the order of 70-320nH) and can allow design engineers a trade-off between how quickly the converter responds to a change in the load current (transient response) verses stability of the control loop. By adjusting the number of phases used in the converter, the designer has flexibility to optimize the circuit for their specific application.

These three new series are available in multiple sizes, inductances, and current ratings. An overview of Pulse’s catalogue of Power Bead inductors can be found online.

| Part Number |

DCR |

Dimensions length x width x height |

Inductance (nH) |

Current (Apk) |

||

| PG2290.XXXHLT | 0.15 | 10.7 | 7.5 | 12 | 120-320 | 140 |

| PGL6395.XXXHLT | 0.23 | 10.2 | 4.6 | 10 | 70-220 | 140 |

| PA5615.XXXHLT | 0.125 | 10 | 6 | 8.5 | 80-100 | 105 |

“With voltage regulator transient response and load line requirements constantly becoming more stricter and demanding, there is significant pressure to reduce losses and increase current ratings while continuing to reduce inductor footprint. Pulse is able to leverage our relationships with our magnetic material suppliers and Power IC partners along with advanced design capabilities to provide optimal magnetic solutions.”

Damon Huang, Product Marketing, Power PBU, Pulse Electronics

Pulse leverages decades of magnetics design experience as well as advanced simulation, testing, and relationships with core vendors to provide leading solutions for high power density and efficiency. Our automated manufacturing strategy allows for cost effective magnetics with high reliability. For more information, samples, quotes, additional inductance values or new design requests please reach out to your local Pulse sales representative or distributor.

To view, compare and download data sheets for our Power Bead Inductor Series utilize our Product Finder and simply enter the prefix of the part number. To inquire about lead times, competitive pricing, samples and more, just contact us or use our quote form accessed using the button below.