Common Mode Chokes are used in power supply circuits for filtering in a wide range of electronic products. Although ubiquitous, their function and basic operation is often poorly understood.

In any modern electronic product, it is highly likely that several different voltages and power conversion circuits will be required for the device to function properly. Creating the functioning circuits is a significant part of the design but ensuring that the circuits do not interfere with one another is equally critical. Radiated and conducted emissions standard (FCC Part 15, CISPR, IEC61000) have been put in place to ensure minimal electrical and magnetic interference. Many best practices exist for designing EMI friendly circuits such as minimizing the length of high current loops, matching input/output impedances, and carefully placing ground references to control current return paths. However, even when these best practices are implemented, many systems still require additional filtering. This additional filtering often is implemented using a common mode filter comprised of capacitive elements and a common mode choke (CMC), which is an inductive element.

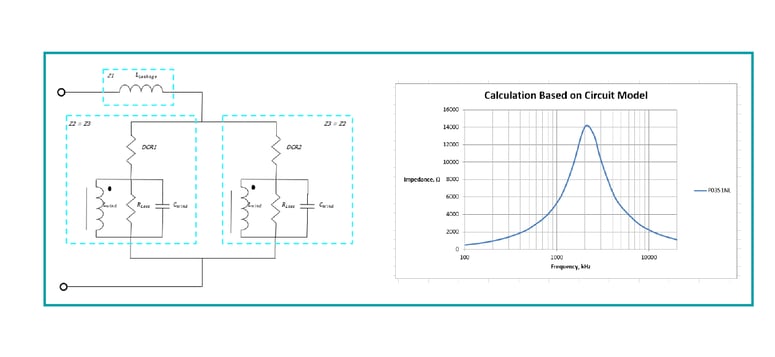

To understand how a CMC works, one must first understand the difference between common mode noise and differential mode noise and then how the non-ideal elements of a CMC impact them. One common misconception is that only the inductance should be maximized to best filtering. In practice, it is critical to maximize inductance but also equally important to minimize parasitic series resistance and winding capacitance. In our white paper, “How Does it Work – Common Mode Chokes” simplified equivalent circuits are used to model graphically and mathematically how each element in the common mode choke impacts it’s impedance versus frequency curve, and consequently filtering performance. By understanding how the parasitic resistances, capacitances, and inductances within a common mode choke Pulse is able to develop more effective filter elements while maximizing the current carrying capability of each component, enabling higher power density.

By understanding how the parasitic resistances, capacitances, and inductances within a common mode choke Pulse is able to develop more effective filter elements while maximizing the current carrying capability of each component, enabling higher power density.

“Pulse offers common mode chokes in several constructions ranging from our popular Self Leaded Inductive Component (SLIC) packages, our new PAC6006.XXXNL EP13, PA5140.XXXNL EP18 and PA5141.XXXNL EP22 platforms, and traditional toroidal designs with ferrite or nanocrystalline cores. The wide variety in our catalog enables design engineers to tackle difficult noise filtering challenges while maintaining efficiency and satisfying mechanical requirements.”

David Wiest | Product Marketing, Power PBU, Pulse Electronics

To view, compare and download data sheets for our products utilize our Product Finder and simply enter the prefix of the part number. To inquire about lead times, competitive pricing, samples and more, just contact us or use our quote form accessed using the button below.