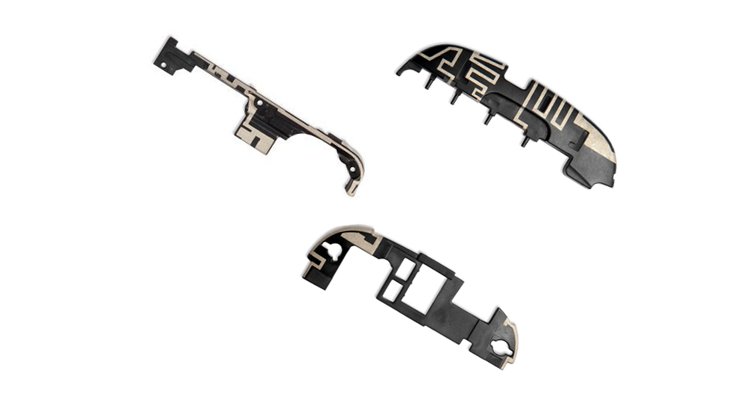

Pulse’s in-house LDS process is the most capable 3D antenna manufacturing process on the market. With the increasing need to make our devices as small as possible, LDS manufacturing optimizes your antennas performance while using the ideal amount of space in your device. LDS technology offers extensive benefits, such as:

- As much as 30% cost savings compared to other lasering techniques

- Rapid prototyping and samples

- Design flexibility during production with low tooling costs

- Fast ramp-up and seamless transfers between R&D and Production

- Allows for additional mechanical integration

Pulse’s LDS manufacturing along with our painting and plating processes, has you covered every step of the way. Our end-to-end product development, with the assistance of our world class engineers will turn your idea into a reality. Contact us today for the endless possibilities of LDS Manufacturing.